-

石墨烯薄膜产品 Graphene film products

Superclean graphene film was obtained by eliminating the contamination formed during the process of high temperature chemical vapor deposition (CVD) growth of graphene.

-

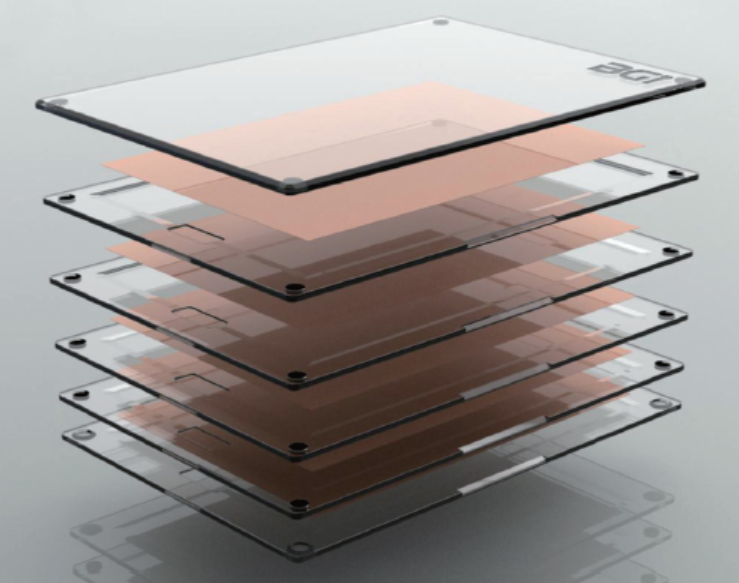

四英寸/六英寸单晶石墨烯晶圆 4’/6’ Single-Crystal Graphene Wafer

The single crystal copper wafer was prepared by the technology of "magnetron sputtering + solid phase epitaxial recrystallization", and then the single crystal graphene wafer was produced by epitaxial growth on the single crystal copper substrate.

-

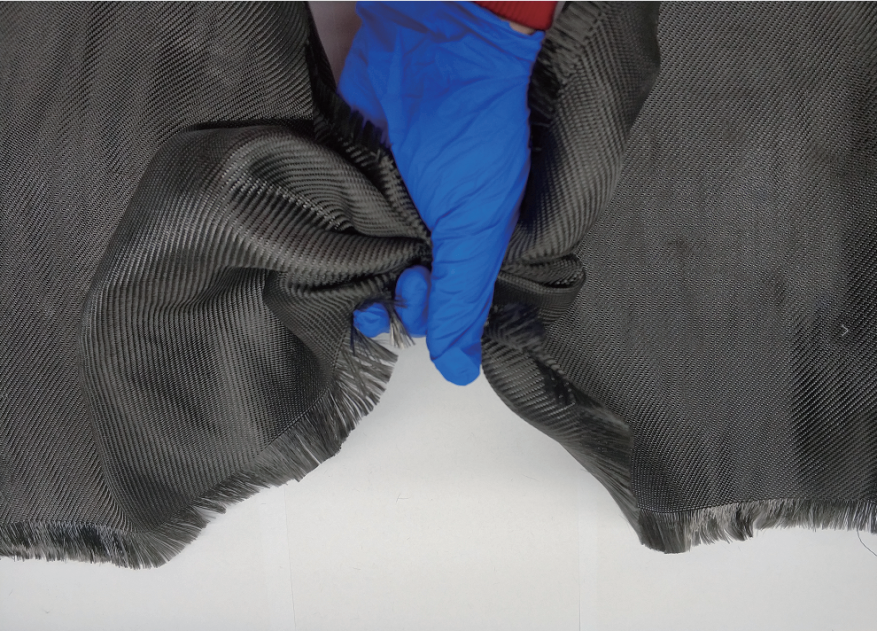

石墨烯玻璃纤维 Graphene Quartz Fiber

We design and develop the batch preparation equipment of graphene quartz fiber, which can realize the continuous, pilot-scale, stable production of different types of graphene quartz fibers or textiles.

-

烯碳/芳纶Ⅲ复合纤维 Carbonene/Aramid Ⅲ Composite Fiber

We use carbonene materials (graphene, carbon nanotubes), to prepare carbonene/aramid Ⅲ composite fibers. Through precise control of the physical and chemical structure of the interface structure, the efficient transfer of stress between the matrix and the reinforcement is realized.

-

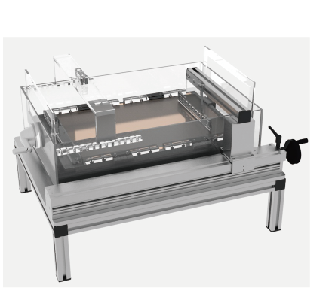

石墨烯制备装备 Equipments

The BGI Equipment R&D Center has developed different types of equipment which according to the market demands in various application fields.

-

微波石墨烯 Microwave Graphene

We produce high-quality, high-purity, low-oxygen small-size graphene powder via a sustainable and industrial scale microwave technology in gas phase. Our graphene powder could be easily applied in electronic ink, composite enhancement, and biomedicine etc.

官方微信